Oil & Gas

Thermography is very useful when inspecting pipes, helping to efficiently locate emissions leaks such as oil or gas. The infrared technology is useful to monitor critical equipment in this sector such as motors and electrical and thermal components. The bcbGasScan system helps to detect these leaks on time, preventing millions of dollars in equipment losses, environmental impacts and even fires.

EXTRACTION AND PRODUCTION

For everything related to gas detection and quantification, the bcbGasScan turns out to be a reliable continuous OGI (Optical Gas Imaging) inspection center, continuously receiving information from one to several cameras and alerting any anomaly through mobile devices. The bcbMonitor 4.0 works in a very similar way, with the difference that the latter is specialized in condition monitoring.

Condition monitoring of critical electrical, mechanical and thermal equipment- Gas leak detection. Some examples:

- -Natural Gas and Hydrocarbons (Methane, Propane, Butane and Ethylene)

- -Carbon Oxide

- -Carbon dioxide

TRANSMISSION AND TRANSPORT

The large production volumes of the Oil & Gas sector require a modern and efficient transmission and transportation system. Kilometers of infrastructure that must be constantly inspected with the intention of preventing losses and in some more serious cases, fires and explosions.

The risk of producing a spark is always present in machines and equipment, a highly dangerous situation when handling flammable substances. With the bcbMonitor 4.0 it is possible to monitor these elements and with the bcbGasScan is possible to prevent and react to any gas leak. Both platforms offer a sophisticated and unattended alarm system, based on FLIR‘s ever-reliable OGI and thermal imaging cameras.

- Continuous thermographic monitoring of:

- -Compressors

- -Pumps

- -Tanks

- Leak detection and emission quantification:

- -Natural Gas and Hydrocarbons (Methane, Propane, Butane and Ethylene)

- -Carbon Oxide

- -Carbon dioxide

PROCESSING AND REFINING

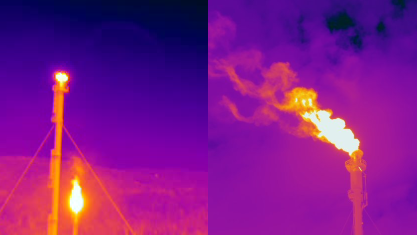

An interesting application for the bcbThermoPro consist on monitoring high-speed rotating equipment, such as turbochargers and expanders. Through a sight glass, a high speed camera can be used to assess the condition of the blades. The bcbMonitor 4.0 is excellent for burner flame monitoring and the bcbGasScan is always useful for gas detection and quantification.

- Furnace inspection (camera to see through flames)

- Flame monitoring in torches.

- Monitoring of equipment and facilities for fire detection.

- Gas leak detection and quantification

Contact

Are you interested in any of our services?

For more information about our products and services, you can contact us without obligation and we will respond as soon as possible.