bcbDieScan

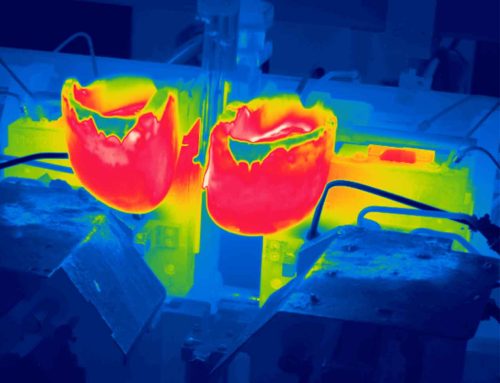

Large temperature differences in the element or in the die during the process, lead to the appearance of non-homogeneous deformation leaving the manufactured part out of its tolerances. This is why it is vital to maintain an adequate temperature of the process.

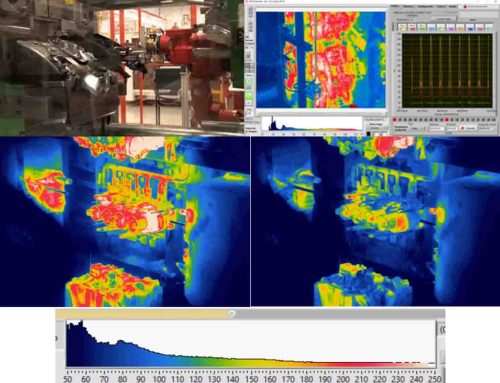

FLIR thermal imaging cameras, together with the bcbDieScan software, allow the entire process to be monitored and autonomously and continuously locate thermal imbalances, generating alarms in different formats that promptly report the incident.

What includes?

System features

- Continuous monitoring of molds

- Out of range temperature alarms

- Temperature measurement in specific areas previously selected

- Robot-assisted thermal inspection

- Image post-processing for process analysis or startup of new lines.

- Simultaneous viewing of multiple cameras and unattended monitoring

- Process traceability diagram

- Communication with company BBDD

- Communication to PLC by ethernet protocols (Modbus, PROFINET, TCP / IP)

- Communication to PLC by serial protocols (USB, RS-232, RS-485)

Industries

Continuous and simultaneous monitoring of critical areas in molds and dies

IP67 protection for environments with high levels of dirt

Features for the efficient development and launch of new products