Aeronautic

In this sector, the integrated systems based on thermography are used in applications such as testing, non-destructive testing, welding and metallurgy. The thermographic systems are based on the bcbMonitor 4.0 which can operate both as a basic processing software with a single camera connected to a PC and as a complete test station with different equipment integrated as well as additional systems

TESTING

The bcbTestBench is a powerful testing tool based on our software, integrated to thermal imaging cameras, applicable to powertrain components, landing gear, and control instruments, just to name a few examples. In addition, it gives the possibility to integrate other sensors. Some elements in which thermographic systems can be applied for inspection and control are:

- Electrical, mechanical and thermal test benches.

- Engines

- Blades.

- Cooling systems.

- Fuselage.

- HVAC components.

- Landing gear components.

NON DESTRUCTIVE TESTS (NDTs)

Active thermography is a highly appreciated technique by NDT specialists. Both, the bcbTestBench and the bcbThermoPro, incorporate advanced techniques for processing, communication and control of every element required for each test, such as infrared lamps, lasers and different types of thermal excitation stations. Some elements in which thermographic systems can be applied for inspection and control in NDTs are:

Stations for inspection of discontinuities with active thermography.- Blades.

- Frames.

- Spoilers.

- Fuselage.

- Stabilizers.

- Fuselage components.

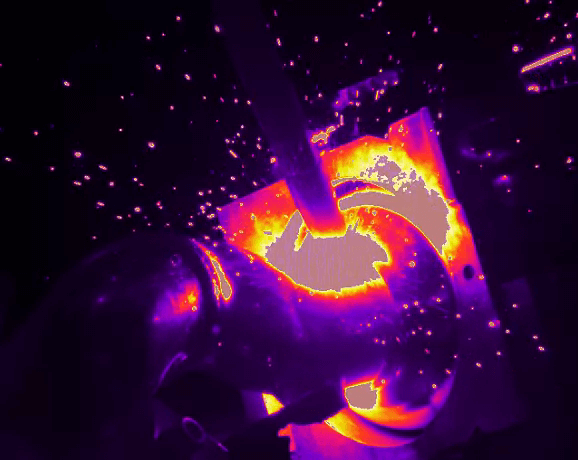

WELDING

The welding process of the engine parts from an aircraft has evolved over the years, offering greater advantages to the manufacturing process of those components. Among the areas of interest of the aeronautical process are the productivity and quality of arc welding, the efficiency and size of fiber laser welding, the size and precision of the linear friction welding machine and the manufacturing quality of laser additives

The bcbMonitor 4.0 is established as a continuous thermographic monitoring system for metallurgical experts addressing thermal bonding techniques. Its traceability and reliability in the inspection using thermal imaging cameras gives this system a high value in the sector, also due to its high compatibility with the other devices used in these processes. Some examples where these solutions are applied are:

- High speed testing of thermal joints.

- Electric arc detection.

- Tungsten Inert Gas Detection (TIG).

- Metal Inert Gas Detection (MIG).

- Resistance inspection (RW).

- Friction control and supervision.

METALLURGY

The aerospace sector is where, possibly, the highest quality and traceability requirements are found for manufactured products. Therefore, exist constant improvement in technologies for processes such as casting, heat treatment and hot forming. Both, traceability and level of quality required, as well as the fact that a piece of scrap represents a huge loss for companies in the sector, a continuous monitoring and control system such as the bcbMonitor 4.0 becomes essential to comply with both mentioned requirements.

- Monitoring and traceability of forging processes (rolled rings, shaped rings, discs, round bars and hollow bars).

- Cast iron (ASTM steels).

- Heat Treatment (quenching, tempering, annealed, aged).

Contact

Are you interested in any of our services?

For more information about our products and services, you can contact us without obligation and we will respond as soon as possible.