Optical coherence thermography for the food industry

Temperature measurement is an important aspect in any industrial process. In food companies, in addition to incorporating a multitude of stages where temperature is present, it is also key to improve quality and safety in the control of production processes. Controlling the presence of carcinogenic and mutagenic products in heat supply processes is a critical aspect to ensure the safety of food.

Substances such as acrylamide or organic compounds such as PAH or AHC can originate during baking, frying, cooking, smoking processes, etc.

In this article we will show how Infrared Thermography is an ideal tool to monitor these processes, since it is a non-destructive and non-invasive technique, without direct contact, capable of covering large measurement areas, quickly and efficiently.

CONTROL OF ACRYLAMIDE FORMATION

Acrylamide is an industrial chemical formed in foods high in carbohydrates, during heating, in conditions of high temperature and low humidity in processes such as baking, frying and toasting. Its content in food is regulated in the EU by Regulation 2017/2158, in force since 2018, which establishes mitigation measures and reference levels to reduce its presence. The food products referred to in the regulation are:

• French fries, chips, snack products, crackers, and other potato dough-based products;

• Bread, bakery products, pastries, cakes and cookies;

• Cereals for breakfast;

• Coffee, roasted coffee, instant coffee;

• Baby foods and processed cereal-based foods for infants and young children

According to EU legislation, acrylamide is classified as:

• Carcinogenic substance in Category 1B

• Mutagen in Category 1B

• Toxic for reproduction in Category 2

The production of acrylamide content in food at the domestic and industrial level is therefore a public health problem. The important factors that influence the acrylamide formation process are the temperature and the time of heating, cooking and frying. In this sense, Infrared Thermography serves to control:

• Frying temperature, since acrylamide is formed from 120ºC.

• Control of ovens at high relative humidity.

• Pre-frying blanching temperature at 70 ° C (10 to 15 min) with a reduction of acrylamide formation of 65% and 96% for French fries and chips, respectively.

CONTROL OF PAH FORMATION

Polycyclic Aromatic Hydrocarbons (PAH) are penetrating environmental pollutants characterized by their carcinogenic and mutagenic potential. PAHs are ubiquitous, not only in all environmental media (air, soil, and water), but also in various foods that we find in our daily lives.

PAHs are mainly formed by pyrolytic processes, such as in grilled or smoked foods. Another efficient route of PAH intake is mainly attributed to activities carried out in the form of cooking (roasting, roasting and frying) and industrial processing. Some factors that affect the formation of PAH are: the heat source, the heating distance, the design of the feeding device and the type of combustion agent (coal, wood, gas and electrical source). In order to avoid the formation of PAH, Infrared Thermography can control the temperature in:

• Frying: PAHs are formed from 150ºC.

• Formation of chocolates: for milk chocolate 49ºC and for dark chocolate 82ºC.

• Bakery oven: PAHs are formed from 150ºC.

• Hot smoking: 130ºC in the cabin and 80ºC in the meat.

• Cold smoking: temperature below 30ºC (regulation of the air or by the passage of smoke through a heat exchanger)

CONTROL OF AHC FORMATION

Heterocyclic Amines (AHC) are organic compounds that have two or more fused aromatic rings and one amine group (-NH2). Like PAHs, they are ubiquitous both in the environment and in various everyday foods. They are characterized by their carcinogenic and mutagenic potential and are formed from:

• Pyrolysis of amino acids: Tryptophan, Lysine, Glutamic Acid and Phenylalanine

• Carbolines

• Reaction between products of the Maillard Reaction and creatine

• Aminoimidazoazarenes

Some factors that affect the formation of AHCs are the type of meat, the duration and temperature of cooking, the cooking equipment and method, the pH, the content of carbohydrates, free amino acids, fat, creatine and / or creatinine. In this context, infrared thermography is used to monitor the temperature in:

• Frying foods rich in protein: cooking meat and fish from 150ºC.

• Industrial ovens from 150ºC.

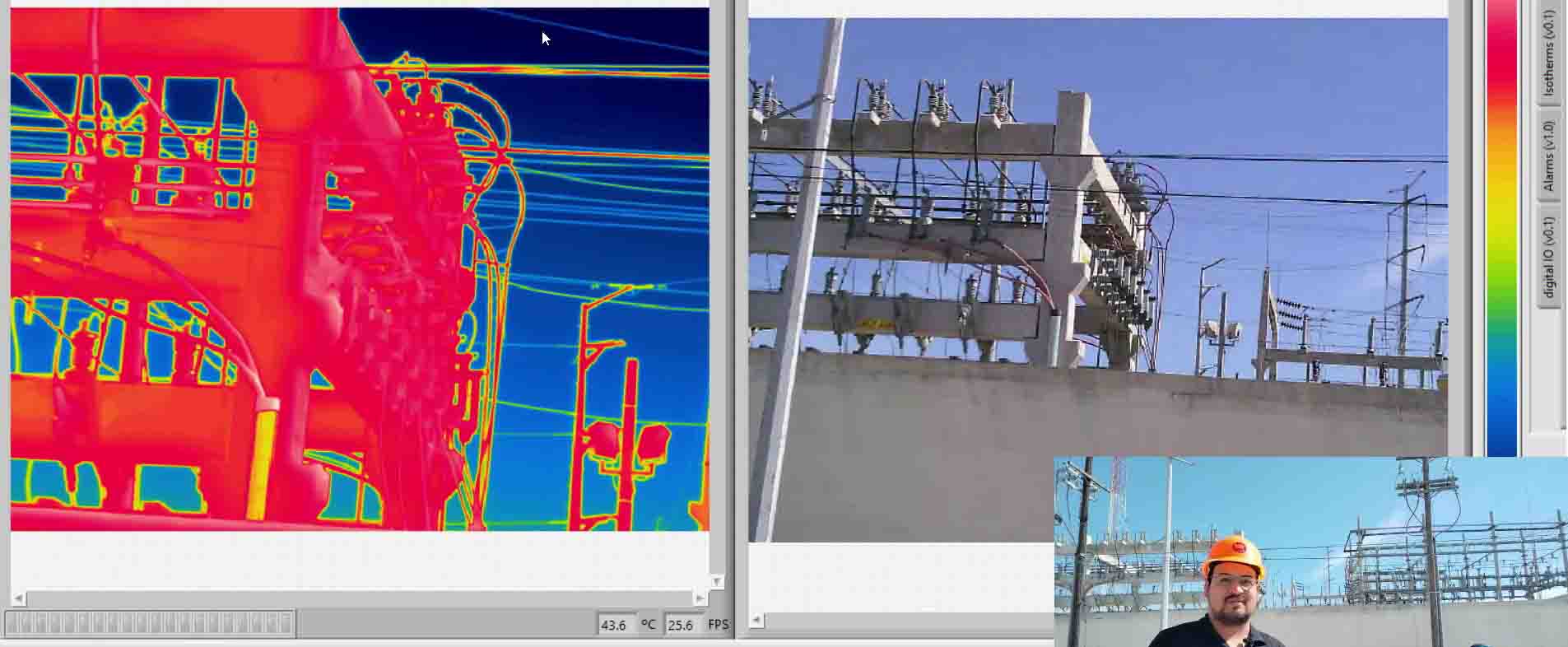

Thermography acts as a non-contact temperature sensor for large areas, being a widely validated non-invasive and non-destructive tool in process control. bcb has extensive experience in thermography, available to the food industry through the bcbMonitor 4.0product range. The automation of the inspection is obtained by treating the images from one or multiple thermal imaging cameras and specific software, which detects deviations in the process and informs the operator or connects with other systems in the production line for their correction.