Implementing thermography, bcb has deployed 2 thermographic monitoring systems for Ahresty Mexicana, a leading automotive company specializing in high-pressure aluminum die casting (HPDC).

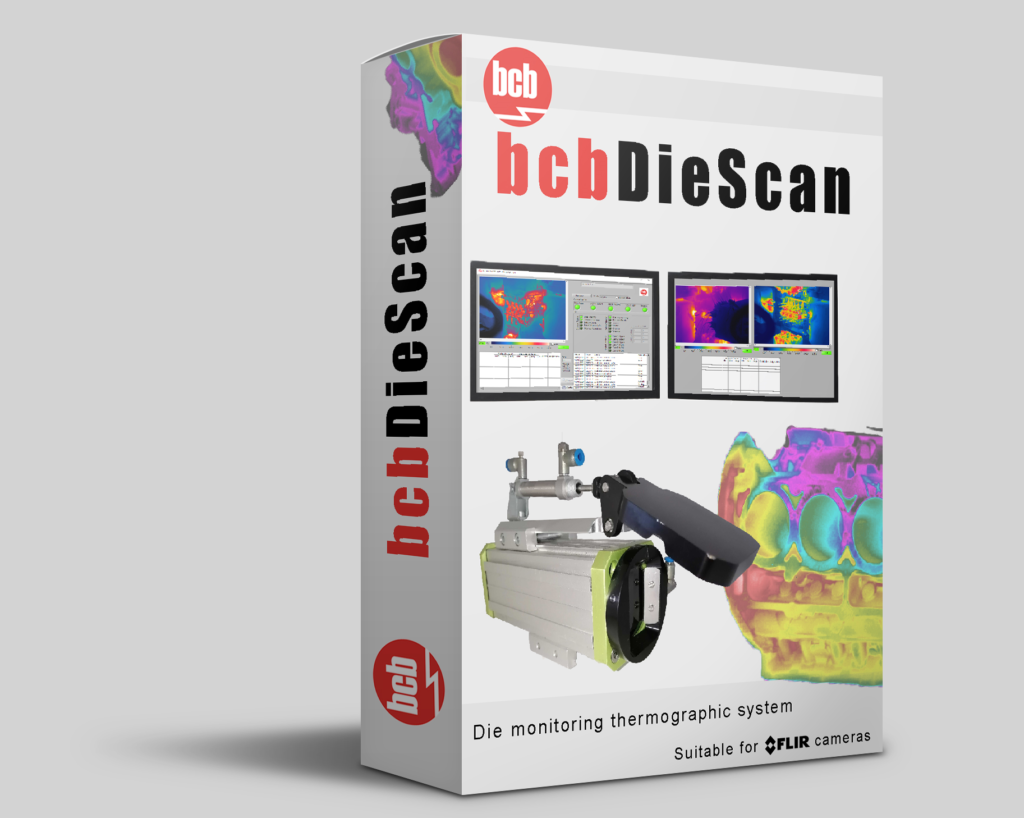

The system consists of FLIR A65 cameras that monitor both molds (fixed mold and mobile mold), and through powerful data acquisition software and a computer with a set of digital cards, bcb analyzes the thermal distribution of both molds using the bcbDiescan software from the bcbMonitor 4.0 family. It is in the lands of Zacatecas where the bcb team, along with the Japanese company, has managed to equip 2 HPDC machines, with a total of 5 cameras currently monitoring both machines.

bcb has always been characterized by surprising the industry with such versatile applications for quality control, and this time has been no exception. Thanks to IR camera technology and software engineering by bcb, such a magnificent proposal has been achieved.

The system is intended to help reduce defects on components that are difficult to detect at first glance, but with surface temperature measurement, this task is performed in a matter of seconds, with the aim of ensuring that internationally renowned assemblers deliver more and better automobiles to cities around the world.